The Brigham distillator system, developed in the 1930s, was created in response to a common complaint of pipe smokers – tongue bite. Eliminating this burning sensation created by the tars and acids of the burning tobacco (especially in wet and aromatic blends) became a consuming passion of ours. We found the perfect taste-neutral and effective material in natural, untreated Rock Maple.

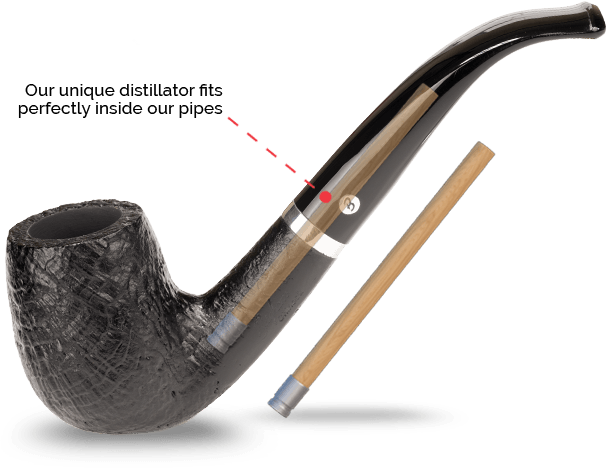

Each distillator is made by hollowing out the inside diameter of a 3.5” Rock Maple dowel and pressure-fitting a special metal cap to its end which helps the distillator fit snugly inside the pipe while making removal simple. The manufacturing process of the distillator uses no chemicals or adhesives to guarantee a taste-neutral system.

Benefits of Our Design

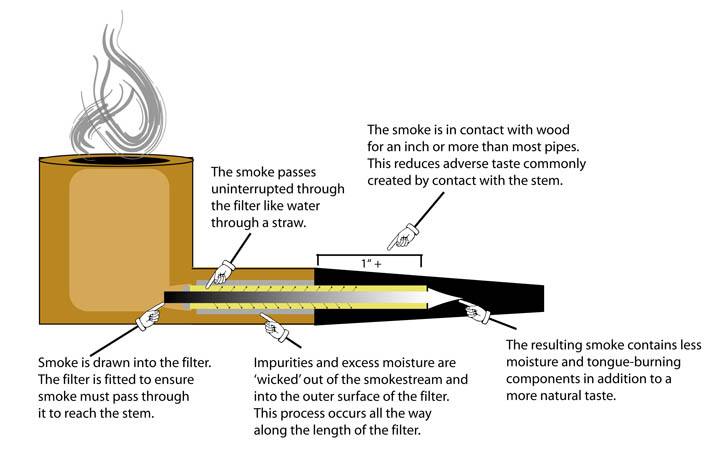

By design, the Brigham system extends into the stem, providing an extra inch of wood through which the smoke passes. Consider that in most other pipes, smoke spends half of its time passing along a plastic or rubber channel which can add negative flavour to the smoke while providing no benefit of its own.

This combination of reduced exposure to plastic and rubber, drastic reduction in tongue bite, elimination of gurgle and flow-back as well as the ease of use has made Brigham Canada’s pipe of choice for generations.

Why use our system?

- Drastically decreases tongue-bite (the burning sensation on the tongue)

- Virtually eliminates gurgle and moisture

- Does not impede airflow – you can pass a pipe cleaner through it

- Does not impart any flavour of its own

- Improves the smoking characteristics of even the wettest tobaccos

- Decreases the amount of contact smoke makes with the stem

- Distillators are easily replaced and can even be rinsed, dried and reused several times

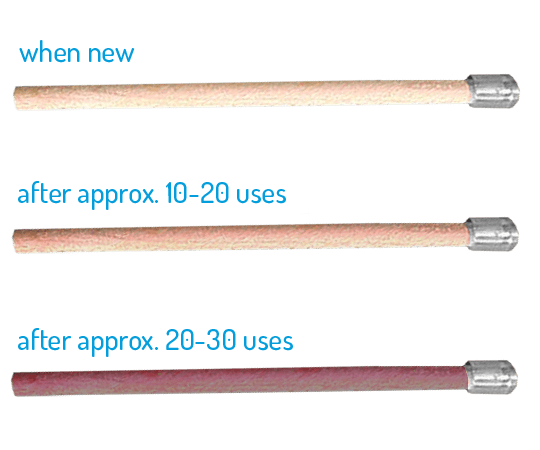

As part of the after-smoke cleaning process, when the pipe has cooled fully, remove the distillator and inspect it. If it is a very dark brown colour, it is time for cleaning or replacing. Being diligent will ensure all the benefits of our system and a dry, clean taste!

Remember that our distillators are very effective sponges and have a finite capacity. Once a distillator has become saturated with moisture and impurities, its effects are eliminated and the benefits lost. Additionally, as the distillator is used beyond saturation, it expands in size to compromise the way it fits into the pipe. It is possible for a distillator to become very firmly wedged in the tenon if left too long. This is not irreparable, but can lead to poor pipe performance and ineffective cleaning.

The easiest approach is to replace your distillator once it becomes dark brown (almost black) with a new one. We recommend alternating between 2 distillators, allowing one to dry while the other is used

Our distillators can be cleaned with water and left to dry before re-using. This is effective in a pinch, however, our studies reveal that this method reduces the distillator’s ability to operate effectively after a few repeats.

The impurities are safely held there until the distillator is removed for cleaning. When a distillator becomes dark brown, it can no longer distillator effectively, and should be replaced. Factors such as the relative wetness of the pipe tobacco, amount of moisture originating from the smoker’s mouth and frequency of use can change the length of time it takes to reach saturation.